Production Process with Paddle Mixer

The SJHS2A Double-circle Mixing Machinery is widely used for mixing powdery and special granular materials in feed industry. Mixing machine is playing a vital role in feed production. It is fair to say that if proportioning system is disjoined from mixer, even with advanced manufacturing processes, the production will become meaningless. Therefore, the quality and performance of mixing machine directly influences survival and development of feed mills. Stable-performance equipment not only helps enterprises to keep making profits but also reduce large sum of money for maintenance and repairing.

(1) Feeding

(1) Feeding

Solid materials

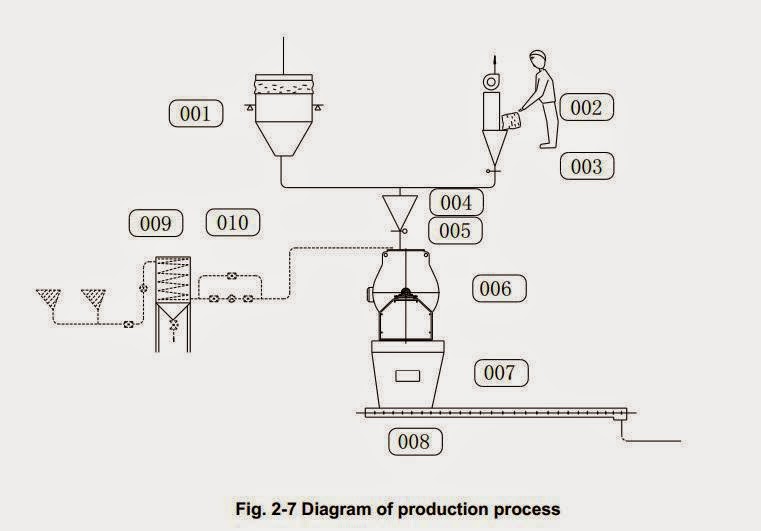

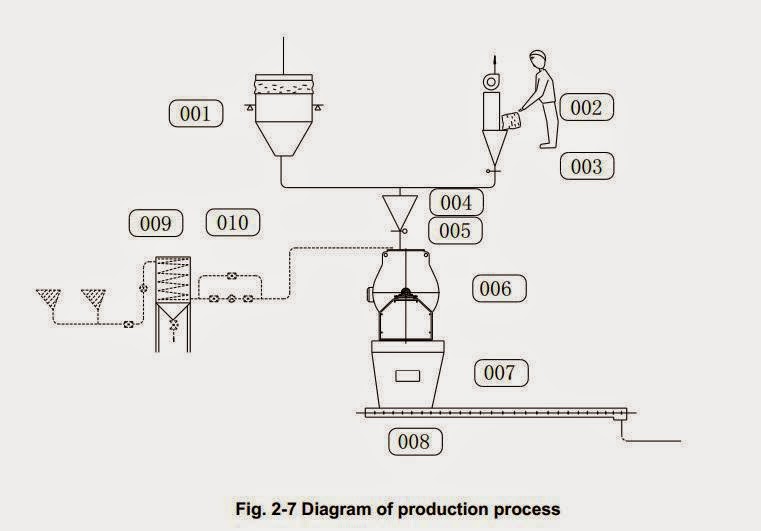

The materials can be directly fed from the bin (see Fig.2-7 005) controlled by a lock gate (see Fig.2-7 006) after weighting with the proportion scales (see Fig. 2-7 001), and also can be fed via a covering equipment or via an operator (see Fig.2-3 003) at the manual dumping bit (see Fig.2-7 004).

Liquid (if necessary)

Liquid is generally fed into the mixing machine via the liquid addition system (see Fig. 2-7 010).

(2) Discharging

The mixtures conveyed from mixer (see Fig. 2-7 007) shall be collected by a surge bin (see Fig. 2-7 008);

And the volume of surge bin should be 1.5 times more than that of feed mixer. The surge bin usually has an access door (manhole) and a glass inspection window; the lower part shall have a lock gate or conveying equipment (see Fig. 2-7 009);

The upper end of air-return duct (see Fig. 2-7 009) is connected to the surge bin or that above the scale to ensure stably feeding. In addition, the surge bin shall be removable for maintainability; the environmental protection equipment can be equipped at the outlet to prevent dust pollution of the surge bin.

Solid materials

The materials can be directly fed from the bin (see Fig.2-7 005) controlled by a lock gate (see Fig.2-7 006) after weighting with the proportion scales (see Fig. 2-7 001), and also can be fed via a covering equipment or via an operator (see Fig.2-3 003) at the manual dumping bit (see Fig.2-7 004).

Liquid (if necessary)

Liquid is generally fed into the mixing machine via the liquid addition system (see Fig. 2-7 010).

(2) Discharging

The mixtures conveyed from mixer (see Fig. 2-7 007) shall be collected by a surge bin (see Fig. 2-7 008);

And the volume of surge bin should be 1.5 times more than that of feed mixer. The surge bin usually has an access door (manhole) and a glass inspection window; the lower part shall have a lock gate or conveying equipment (see Fig. 2-7 009);

The upper end of air-return duct (see Fig. 2-7 009) is connected to the surge bin or that above the scale to ensure stably feeding. In addition, the surge bin shall be removable for maintainability; the environmental protection equipment can be equipped at the outlet to prevent dust pollution of the surge bin.

muyangsales - 16. Mär, 03:25